Inflation, supply chain disruptions, labour shortages and pressure to innovate, driven by changing client expectations and the constant need to improve time to market, are just some of the challenges smart manufacturing can resolve.

“To increase competitive advantage, many manufacturers in Asia-Pacific and Malaysia are hoping to capitalise on smart manufacturing, [which is] the concept of integrating technologies, data processes and human interaction to improve production results,” says Eric Chan, vice-president of the network and edge solutions group at Intel Malaysia.

“Smart manufacturing integrates data and information from multiple applications, processes and products that can be composed to form new solutions. It enables predictive and adaptive manufacturing and supply chain processes that allow businesses to fulfil requests for customised products more effectively and to respond quickly to fluctuations in markets through demand forecasting.”

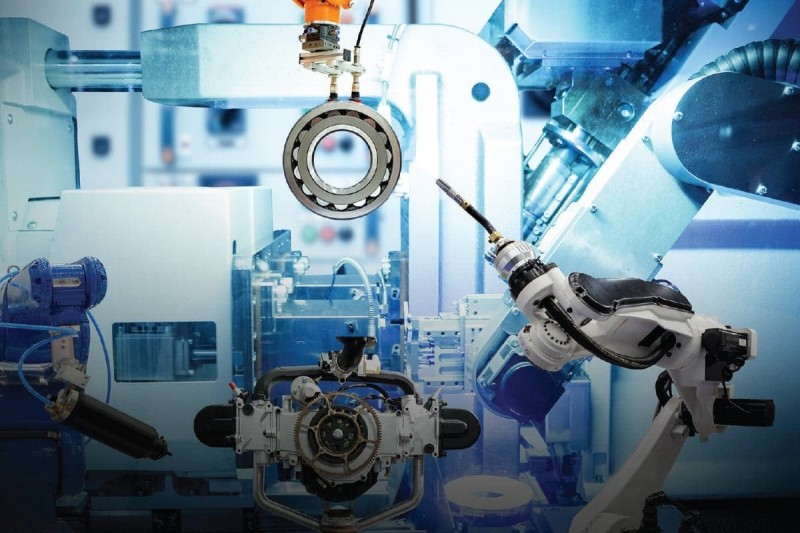

Manufacturers can use intelligent edge platforms, and distributed High-Performance Computing (HPC) systems are some of the paradigm shifts enabling manufacturers to be smarter, safer and more efficient.

Intelligent edge refers to the analysis of data and the development of solutions at the site where the data is generated. With the tool, manufacturers can reduce cost, improve security, heighten productivity and improve real-time performance. It also allows manufacturers to run multiple workloads in standard equipment, which eliminates the need to move large volumes of data from on-premises to the cloud.

Moreover, it enables comprehensive quality management through near real-time product defect detection, process and supply chain optimisation and an increase in asset utilisation.

“Intelligent edge systems are the backbone of Industry 4.0 and smart manufacturing. They enable data and information from multiple sensors, applications and processes to be analysed closer to the source, which helps reduce downtime, optimise operations, automate processes and inform new solutions,” says Chan.

“Software-defined infrastructure enables near real-time analytics across the supply chain to further advance efficiency, productivity and data visibility.”

With HPC systems, manufacturers can run highly complex workloads such as crash simulations or fluid dynamic modelling within acceptable time parameters.

“As operational technology (OT) and IT converge, HPC for manufacturing allows manufacturers to deploy modelling and simulation workloads on distributed HPC systems, both in the cloud and on-premises, to help enhance product design, identify product challenges and improve business results,” says Chan.

“OT and IT have traditionally operated separately. Owing to the advances of Internet of Things (IoT), machine-to-machine communication and data analytics, OT and IT can converge, and IT can break the conventional OT information silos.

This is achieved by the sharing and processing of data exchanges across the manufacturing floors, which enables better productivity, automation and streamlined workflow.

“Convergence is the key. Don’t just stop at tuning the OT to be software-defined; it gives you only half the value. To achieve true OT-IT convergence, further integration of manufacturing data from these technologies with business intelligence, such as enterprise resource planning or supply chain management systems, is needed,” says Chan.

“[This will] further influence the decision-making outside of the factory, be it in supplier management, accounting or compliance. New technologies and interoperability are only the first mile of the smart manufacturing journey.”

Improving productivity

There are a host of benefits for manufacturers to go down the smart manufacturing route, he adds.

For instance, smart factories demonstrate an array of operational benefits, such as digital twins, to allow technology and operational simulation, real-time control systems to provide a safer working environment, artificial intelligence (AI) detection for full production quality inspection and autonomous mobile robots to improve production flow.

One such example is UWC, a metal sheet casting manufacturer that provides metal fabrication and value-added assembly services to the semiconductor industry.

“As the business environment becomes more competitive, UWC is looking to deploy the AI machine vision to replace their current manual defect and quality inspection in their manufacturing process. UWC turned to Intel for help to address floor challenges with AI,” says Chan.

The AI machine vision is based on various Intel solutions that will enable UWC to reduce quality inspection time to a fraction of the current process based on the lab-test results, adds Chan.

As such, there are a few steps that organisations can take to ease into smart manufacturing. First, organisations should seek external help to get an outsider’s perspective on the manufacturing process while looking for a suitable systems integrator.

“These third-party perspectives are vital in helping plan the transformation holistically so that the organisation has the right expectations on when they can truly see return on investment. This also enables the business to put in place the right capital budgeting model to evaluate the investment,” advises Chan.

Moreover, organisations should opt for an open platform, which will provide greater flexibility on the plans and technologies used.

“An open, fully programmable and standards-based unified system provides manufacturers with the choice, flexibility and interoperability to optimise operations and drive innovation regardless of the vendors or suppliers they use,” notes Chan.

“It is also important to have an underlying architecture that simplifies OT-IT convergence and enables software-defined manufacturing.”

There are myriad challenges for manufacturers to further tackle, talent being a key obstacle in transformation efforts. As such, talent development is essential to equip the current and future workforce with emerging skills while investing in research and development.

Intel Malaysia works with various government agencies, universities and schools on programmes to accelerate the adoption of digital skills.

“Malaysia is competing for talent with neighbouring countries, and the shortage of talent is an ongoing challenge for manufacturers in [the country]. The current and future workforce needs to embrace new and emerging skills. Smart manufacturing is a great example of that and can provide an opportunity to create higher-skilled jobs,” says Chan.

Other challenges that manufacturers face, such as the disparity between small and medium enterprises and multinational companies, will need to be addressed by making technology more accessible to all.

Despite these challenges, smart manufacturing remains a necessity to optimise operations.

“The smart manufacturing transformation is a journey that every manufacturer will need to take, sooner or later. It is not really a choice of whether or not to do, because it will be a necessity required to build resiliency and competitiveness,” says Chan.

Source: https://theedgemalaysia.com/node/681832